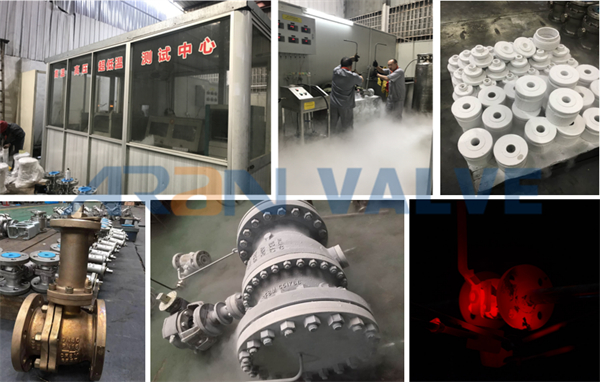

Quality Equipments And Quality Control Process

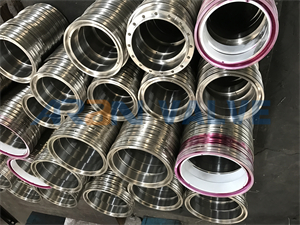

All the valves are executed by good quality control system,reliable inspection tools and well trained QC workers, ARAN keep the quality as the highest importance to our customer.

ARAN has own in-house testing department and also third party authorized lab for special quality control, all inspections and tests are performed by qualified and experienced stuff.

The in house quality control equipment facility,which is for the impact test, hardness test,tensile test,chemical composition and mechanical property lab etc.

Upon order the Quality Control Plan (QCP) and Inspection and Inspection Test Plan (ITP) can be issued for Client approval before production.

1. Valve raw material control: Visual and dimension inspection, PMI,Wall thickness, Impact test if by request, NDE like PT,UT,MT,RT.

2. Valve component machine process inspection: dimension check, machined surface and parts material check, special request like NDE test by order request.

3. Valve assembly and performance inspection: Each piece of the valve is under hydraulic and air test the performance inspection according to order standard request, special request like PAT test by order request.

4. Valve Paint, package and delivery. Special request like third party inspection by order request.

General Quality Contorl Process

Valve raw material control: Visual and dimension inspection, material check,PMI, Wall thickness, Impact test if by request, NDE.

Valve component machine process inspection: dimension check, machined surface and parts material check, special request like NDE test by order request.

Valve assembly and performance inspection: Each piece of the valve is under hydraulic and air test the performance inspection according to order standard request.

Valve Paint, package and delivery.

Special Quality Contorl Request

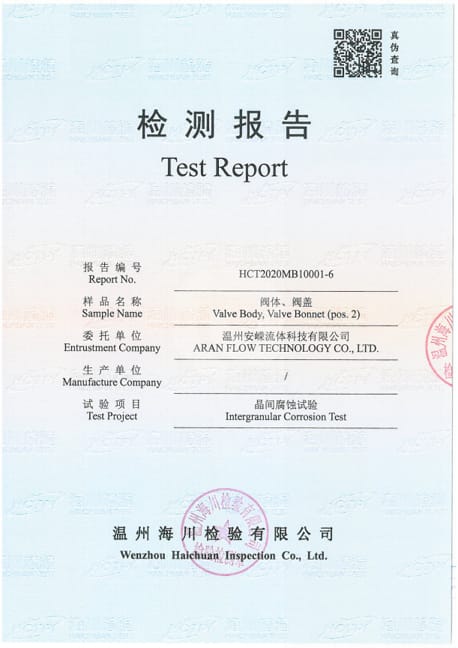

Material test report in third party lab

- Mechanical and impact test

- Chemical analysis check

- Corrosion test

- Ferrite check

- Hydrogen inducted cracking test (HIC)

- Sulphide Stress corrosion cracking test

Non-Destructive test (NDE, NDT)

The performance of VT,PMI,UT,PT can be done by in house and third party doing UT,PT,MT,RT and hardness, and include stuff qualification level which all will be done acc. to customer order needs.

- VT (Visual Test)

- PMI (Positive Material Identification)

- UT(Ultrasonic test)

- PT(Penetrant test)

- MT(Magnetic particle test)

- RT (X-Ray test)

- Hardness test

Pressure & functional Test

Test standards like API 598,API 6D,ISO 5208,EN12266-1,GOST 9544 etc.

- Functional Test/ Torque value test

- Hydraulic test /Air test

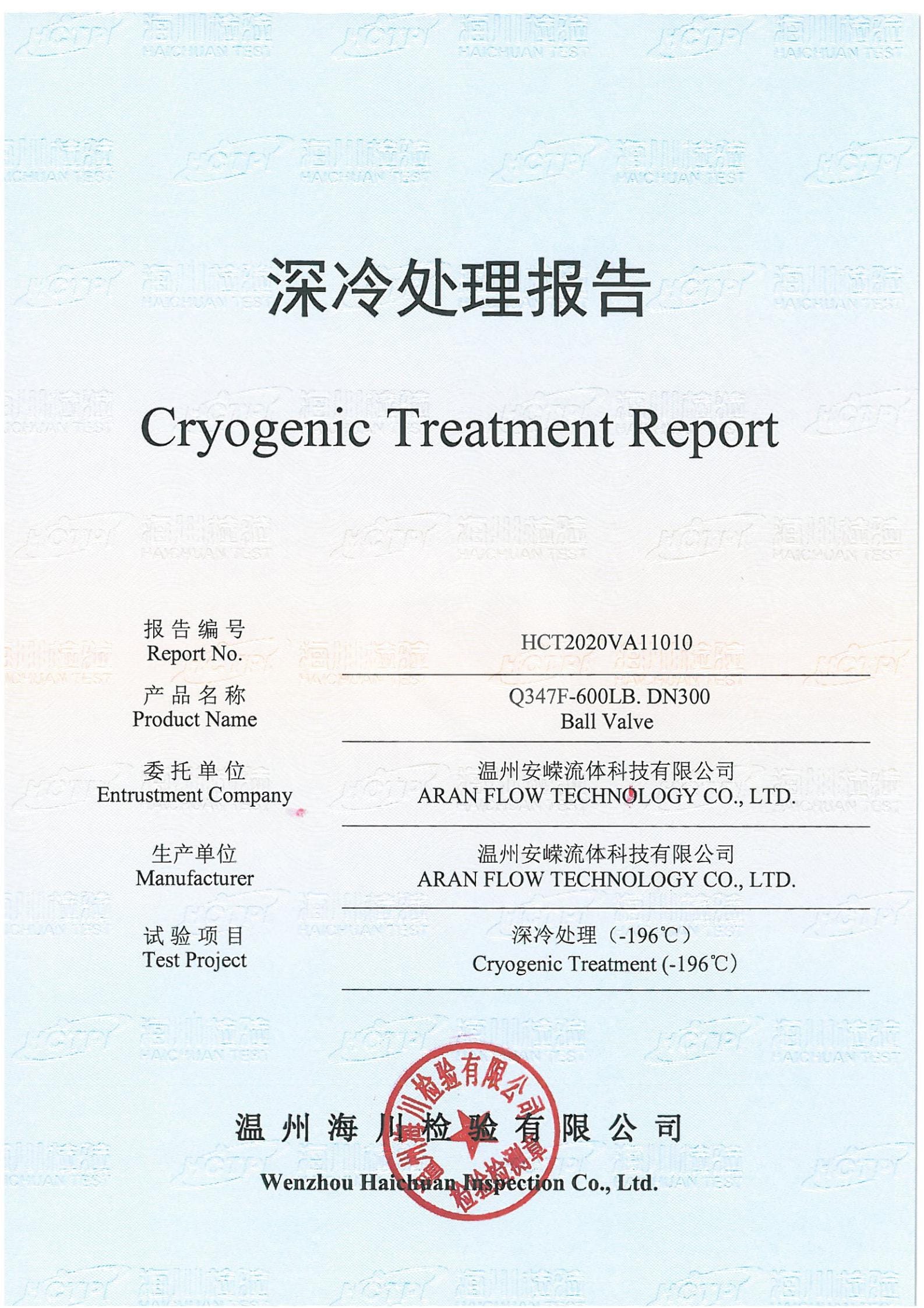

- Low temperature Cryogenic Helium gas test -196°C

- High temperature test 600°C

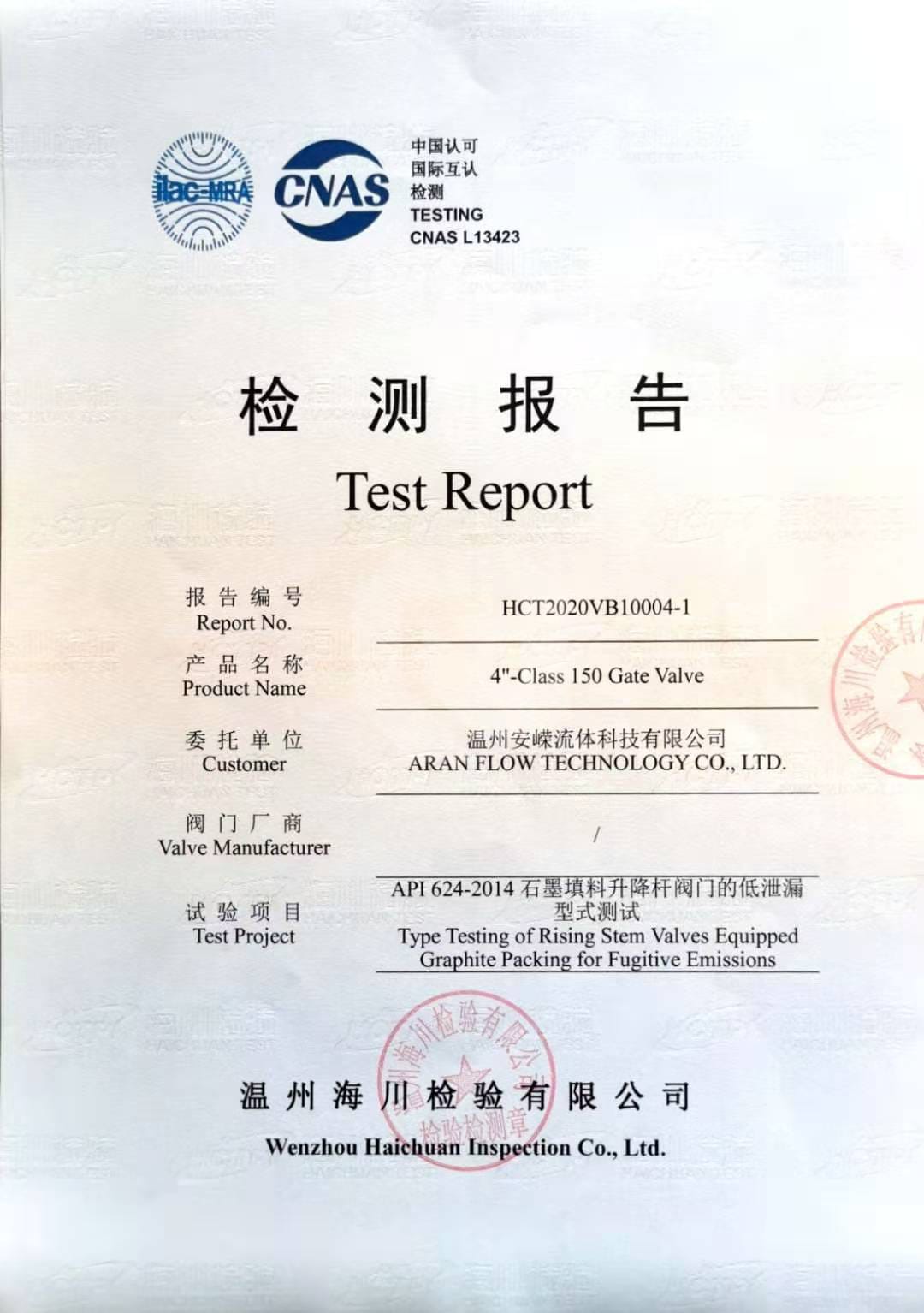

- Fugitive Emission test 15848-1 or 15848-2

- Fire-safe test

- FAT test (factory acceptance test)

- PAT test (product acceptance test)

Low temperature Test: the low and high temperature lab facilities to perform low or high temperature tests in accordance with order requirements. The test exposes the valve to a test low temperature Cryogenic test -196 ℃ or high temperature -538 ℃