Fully weld ball valve /Full weld ball valve/Welded ball valve

Fully weld ball valve /Full weld ball valve/Welded ball valve

- Full welded body ball valves is split body designed, valve body assembly by full welding, without bolted connections,so there is no body leak through bolt connection, avoid any no external leakage risk.

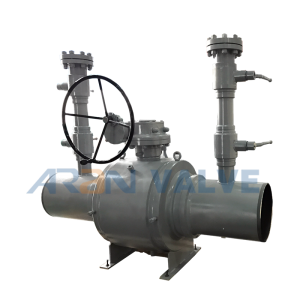

- The full welded body means the valves is impossible to do disassembly maintenance. So the full weld body ball valves used at underground or buried application where maintenance is not expected such as gas transmission, sub-sea application etc.

- Due to impossible to do disassembly maintenance, the ball valve requires accuracy machined and assembled to ensure high performance.

ARAN use all CNC machined ball valve parts and highest standard welding machine assure the full weld ball valve high performance and durable.

ARAN use all CNC machined ball valve parts and highest standard welding machine assure the full weld ball valve high performance and durable.- ● The valve body structure is integrally welded, and there will be no external leakage.

- ● Forged steel body by welding, the forging material inspect by UT and the welding butt ends by PT in comply with ASME VIII NDE control.

- ● The welding process performance qualified and operated by certified technician.

- ● The body and ball are precision machined and grind by accuracy machine, light torque, smooth operation and long service life.

- ● Full bore port maximum flow capacity for pig valve. Reduced bore also available upon request.

- ● Material optional produce comply to NACE MR0175/ISO15156 or NACE MR0103.

- ● The valve seat is composed of a PTFE sealing ring and a spring, which has strong adaptability to changes in pressure and temperature, and will not produce any leakage within the scope of use.

- ● The anti-leakage structure of the valve stem, there is a PTFE self-sealing gasket and an O-ring at the bottom of the valve stem, and there are two O-rings and two PTFE sealing gaskets on the top to ensure no leakage.

- ● The material of the valve body can be forged steel

- ● Metal seat or soft seat selection for different working medium.

- ● Production standard by API/ANSI/GOST/DIN/GB standards

- The directly buried underground extend stem welded ball valve can be directly buried in the ground, without the need to build high and large valve wells, only need to set up small shallow wells on the ground, which greatly saves construction costs and engineering time.

- The length of the valve body and the height of the valve stem can be adjusted according to the construction and design requirements of the pipeline.

- Full weld ball valves are widely used in long-distance pipelines such as natural gas, petroleum, heating, chemical and thermal power pipelines, and other general industrial and oil& gas applications.

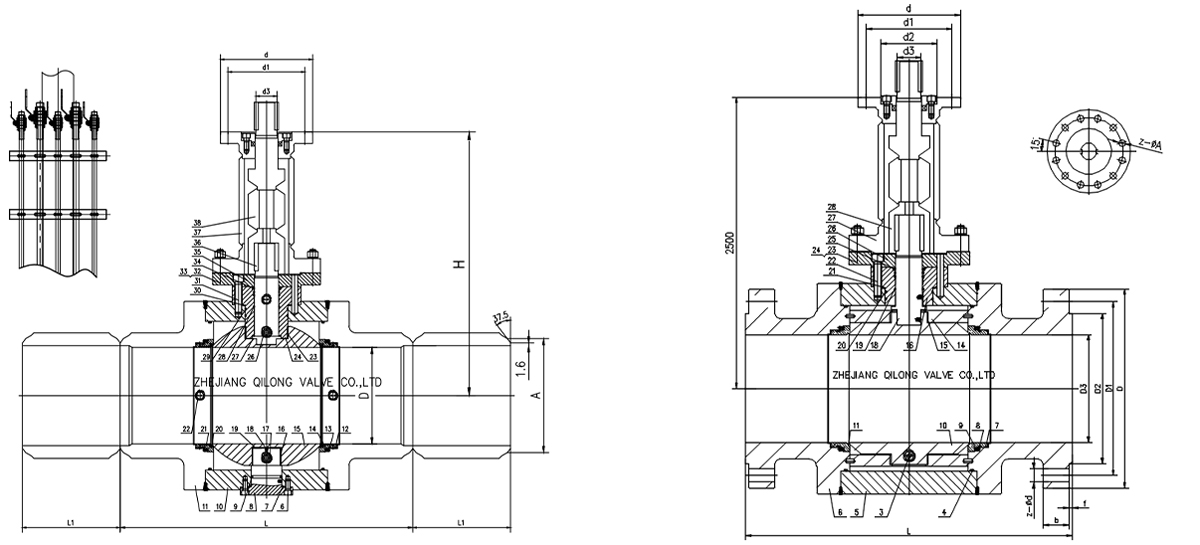

- Fig.Full weld ball valves butt weld end with extend stem and pup piece and pipes Fig.Fully weld ball valve flange ends with extend stem for under ground service

- The natural gas transmission and heating systems above ground and underground is most prevail application for QILONG welded ball valve.

- The construction and maintenance of gas supply pipelines and heating supply pipelines require short construction time and high safety. The fully welded ball valve can be directly buried deep underground. The full weld ball valve applied the latest engineering technology, reduce the assembly space, avoid any leakage explosion risk, can minimize construction cost and engineering time. The bolted bonnet valve couldn’t do directly buried service and need installed in under ground room which is a lot of cost.